Ghilotti Bros., Inc.

“If my generator or backhoe isn’t where it’s supposed to be and I need to find it, it only takes two clicks for me to track my machines down.”

Victor Miral, Service Manager, Ghilotti Bros., Inc

Bay Area construction company relies on Samsara for efficiency, safety, and asset tracking.

140 vehicle gateways and 20 asset gateways provide real-time location visibility of their fleet, generators, office trailers, and other equipment

Preventative maintenance reports track engine hours and fuel usage, in conjunction with fault code alerts, to keep up with specialized needs across the fleet

Driving data and harsh braking alerts on the Samsara dashboard support fleet safety program

Over 100 years ago, Italian immigrant James Ghilotti settled in Northern California and started a small construction business. Since then, three generations of the Ghilottis have built Ghilotti Bros., Inc. into an industry-leading construction company, known for quality craftsmanship and a close-knit culture.

Regarded as one of the most forward-thinking construction firms in the San Francisco Bay Area, Ghilotti Bros. has been involved in hallmarks of construction innovation, such as the iconic Golden Gate bridge, the famously curving Lombard Street, and runways at both the San Francisco and Oakland airports.

For more than a decade, Ghilotti Bros. has leveraged technology to distinguish itself from the competition, adopting digital solutions that streamline operations, increase productivity, and improve safety. When company leaders started looking for a new fleet management system in 2017, they knew they wanted more than GPS location tracking. Ghilotti Bros. also wanted to find an integrated solution that would help protect their 175 employees, their equipment, and their brand.

Ghilotti Bros. found an answer and a partner in Samsara. By combining data from sensors, real-time GPS, dash cameras, and mobile apps into one straightforward interface, Samsara’s platform provides Ghilotti Bros. with unprecedented levels of visibility into their operations and creates opportunities to make the company safer and more efficient.

Improved Efficiency with Real-Time Fleet and Asset Tracking

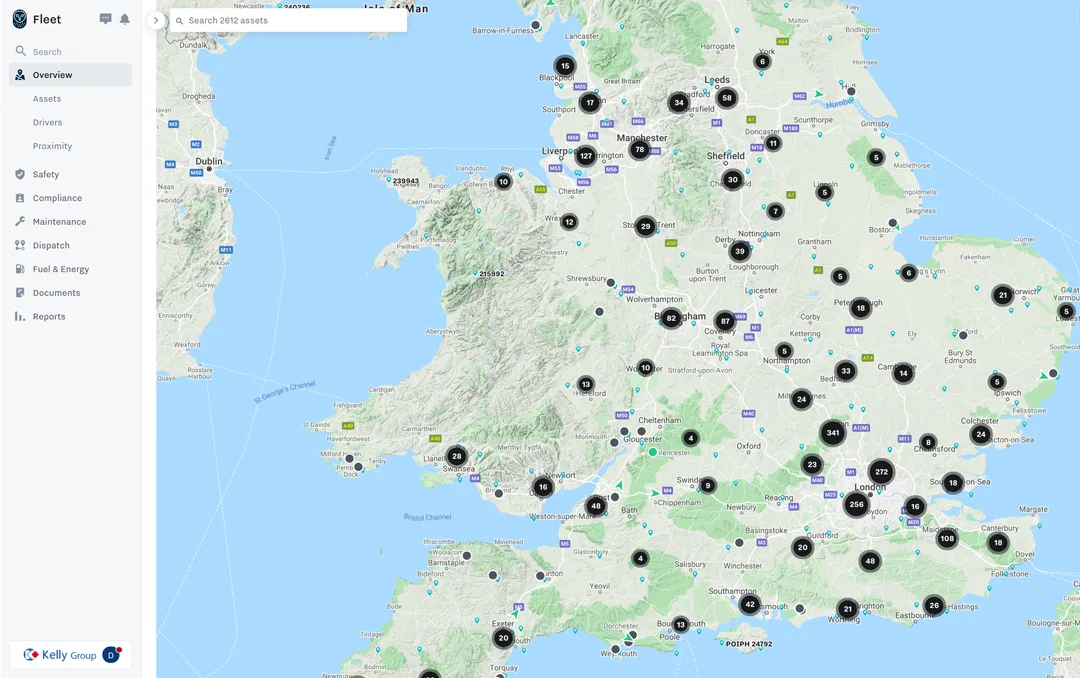

Service Manager Victor Miral was impressed by Samsara’s real-time capabilities and the benefits that came with GPS tracking. Using live location information from Samsara's vehicle gateways, Miral is able to keep up with the constantly moving parts of his white fleet. With Samsara asset gateways, he is also able to track high-value construction equipment including generators, trailers, and large machinery.

“We have a lot of vehicles and equipment spread out across multiple job sites,” said Miral. “If my generator or backhoe isn’t where it’s supposed to be and I need to find it, it only takes two clicks for me to track my machines down.”

The company saves dozens of man-hours each year by avoiding lengthy yard hunts and unnecessary equipment transfers to and from different job sites. Geofence alerts also help Ghilotti Bros. prevent theft by sending a warning when an asset is moved from a particular location.

Streamlined Operations with Preventative Maintenance Alerts

With hundreds of trucks and pieces of equipment, Miral and his team value the ability to streamline their operations with Samsara’s preventative maintenance reports and alerts. Samsara tracks the usage of Ghilotti Bros. vehicles, powered assets, and unpowered assets, automatically reminding the team about oil changes and maintenance checks on tires and other components. The company uses this feature to properly service vehicles and assets, reduce costs, and avoid breakdowns. For example, two trucks with the same make and model may need dramatically different maintenance schedules based on how they’re being used. Vehicles that mostly drive over paved roads don’t need tire changes as frequently as trucks that drive over dirt or gravel on construction sites. Depending on usage, Ghilotti Bros. is able to customize maintenance alerts for each vehicle and asset.

But for Ghilotti Bros., the platform’s safety tools top the list of Samsara benefits. According to the Bureau of Labor, construction is one of the most dangerous occupations in the United States. With drivers crisscrossing job sites, safety is always front of mind for the company, and Ghilotti Bros.’ leadership is constantly searching for better ways to protect their team.

Beyond standard practices, such as mandating the use of safety gear like hard hats, vests, and protective glasses, the company conducts safety huddles every morning and afternoon to identify ways the team can improve. Administrative Manager Gwen Mayer plans a company-wide Safety BBQ every quarter where team members get an update on the company and receive safety training over a shared meal. Ghilotti Bros. tracks safety performance over time, currently clocking in at 375,000 man-hours safe -- accident and injury free -- since March 2017.

Samsara’s safety reports empower Ghilotti Bros. in their mission to create an accident-free work environment. By detecting and capturing information on driver behavior, such as speeding incidents and harsh driving events, Samsara’s platform gives the company the information they need to coach their drivers on safety best practices. Ghilotti Bros. also uses this data to incentivize responsible driving, helping build on the company’s safety-focused culture.

“At Ghilotti we view our team as our family, and Samsara helps keep our family safe,” said Mayer.

Ghilotti Bros. and Samsara have forged a strong relationship, built on their shared commitment to safety best practices and operational efficiency. With Samsara’s all-in-one system and constant innovation, Ghilotti Bros. is well-positioned for continued success.

Similar posts like this

Ruban Bleu ramps up its energy, digital and social transition with Samsara

Samsara technology is helping RubanBleu to deploy a 100% clean fleet by 2026 and reduce its fuel consumption, while improving the safet...

How OMC Global raised safety and customer service standards with Samsara

OMC Global is a luxury transport provider that redefined fleet operations, driver safety, and customer service standards through AI Das...