Get the latest from Samsara

Subscribe nowIt takes a lot of effort to keep a fleet consistently up and running. Even under the best of circumstances, it can be challenging to juggle routine fleet maintenance amidst all the moving parts of fleet management and logistics. When breakdowns crop up or when a vehicle needs to visit the shop for unexpected repairs, your fleet maintenance plan quickly goes out the window.

So how do you keep your fleet chugging along and all your vehicles out on the road? Implementing preventative maintenance strategies and defining key metrics to measure success can go a long way towards putting you in control of your fleet maintenance.

<br>

<div class="text-center"><a id="blog-inline-1" href="/learn-more" title="Learn more about Samsara" class="btn primary-btn teal btn--blue">Learn more about Samsara</a></div>

Be proactive, not reactive

As in life, when it comes to maintenance, it’s best to address issues before they become problems. Last-minute emergency repairs can be up to 4 times more expensive, so it really pays to invest in a preventative maintenance plan and help your bottom-line.

The owner’s manual will tell you the manufacturer’s recommended maintenance schedules or intervals, but keep in mind that service intervals also depend on vehicle operating conditions. In most fleets, vehicles operate under severe duty, meaning that they require more frequent maintenance. To ensure your fleet maintenance is consistent, it’s important to set the same maintenance triggers for all vehicles or pieces of equipment of a particular class, whether that be mileage for light duty vehicles or engine hours for construction equipment.

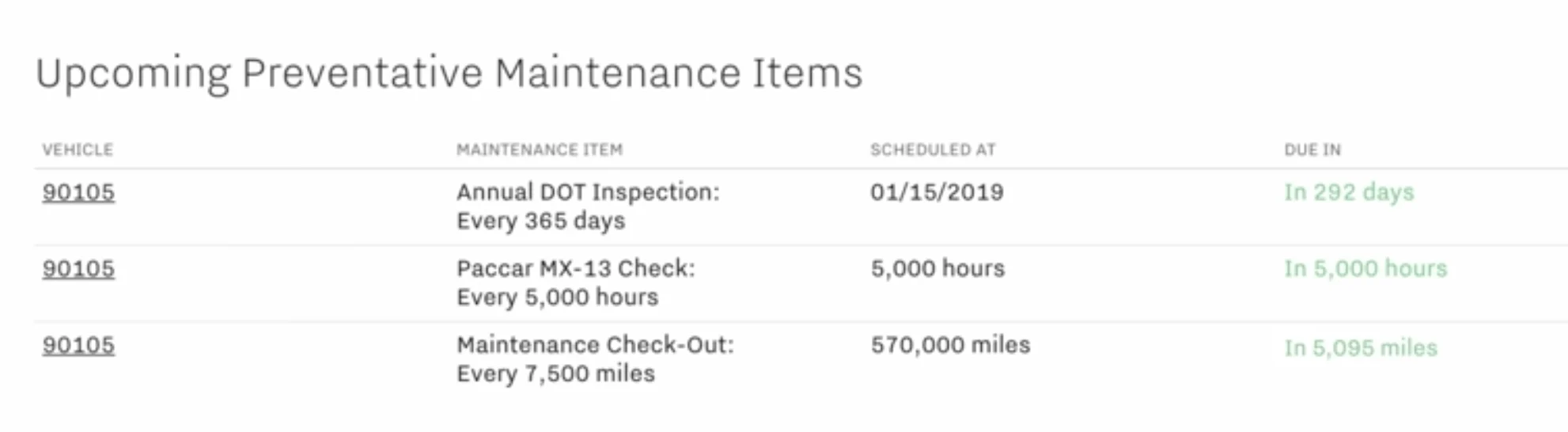

Fortunately, it doesn’t have to be a hassle to keep track of which vehicles need service when. Technology platforms or fleet management software can simplify preventative vehicle maintenance scheduling and allow you to ditch the spreadsheets. Samsara, for example, lets you schedule preventative maintenance not only on time intervals, but also based on a vehicle’s engine hours or mileage.

Define success with target metrics

Once you have a fleet maintenance program in place, you have to determine whether or not it’s working. Tracking your fleet availability will show you how downtime is impacting your operations. To calculate your fleet availability, use the following formula:

Fleet availability = 100% - (Overall downtime / Overall potential hours)

This number should be close to 100 percent, and as you implement more effective fleet maintenance, you should see your fleet availability percentage climb.

As you shift to a preventative maintenance plan, you should see the amount of unplanned repairs decrease. To make sure the ratio of planned to unplanned vehicle maintenance is moving in the right direction, find your preventative maintenance (PM) ratio. A good benchmark to aim for is 70 percent preventative tasks and 30 percent non-preventative tasks.

PM ratio = PM tasks / non-PM tasks

You can also assess if your preventative maintenance plan is working by tracking the mean time between failures (MTBF). This is the average number of hours or days between non-scheduled repairs. With robust preventative maintenance, this metric should increase.

Keep everyone on the same page

Creating a centralized source of data enables fleet maintenance to run as smoothly as possible. If drivers, mechanics, and fleet managers all have access to the same information, it’s easy to see when reported issues have been fixed, a particular vehicle is out of service, or scheduled maintenance has been completed.

Technology is making it much simpler to collect and distribute this information. Samsara pulls data directly from each vehicle’s onboard diagnostics port to track things like mileage, fuel levels, battery health, and engine faults. This information is collected in an online dashboard that allows you to quickly identify issues, see when the last service was performed, and schedule regular check-ups. Closing the loop is a mobile app where drivers complete pre- and post-trip inspections. These paperless DVIRs are instantly sent to mechanics for review, ensuring issues are addressed in a timely manner and vehicles are operating safely.

<br>

<div class="text-center"><a id="blog-inline-1" href="/learn-more" title="Learn more about Samsara" class="btn primary-btn teal btn--blue">Learn more about Samsara</a></div>

Secure driver buy-in

Fleet maintenance is a collaborative process between drivers and mechanics. Drivers are likely to be the first to notice an issue with a vehicle, so it’s key to promote a good relationship between your maintenance team and your drivers instead of falling into the fleet maintenance division. If any driver habits are affecting the maintenance of the vehicle, that conversation should come from the supervisor, not the mechanic, to avoid adding friction to the maintenance workflow.

By empowering drivers to take ownership of fleet maintenance, they become invested in the process. You could even try running a friendly competition to see whose vehicles have the best PM ratio to encourage drivers to report issues as soon as they spot them.

Invest in reliable vehicles

Proactive fleet maintenance means looking ahead, not just in terms of downtime, but for long-term fleet planning. By measuring your fleet maintenance actions, you’ll see how different types of vehicles are performing. Are certain models more prone to breakdowns and higher maintenance costs than others? Armed with this data, you’ll be able to make wise investments in future vehicles and build out a high-quality fleet that spends more time on the road and less in the shop.

Interested in tracking your fleet maintenance through Samsara’s integrated platform for GPS tracking, dash cams, compliance, and more? Sign up for a free trial!

Get the latest from Samsara

Subscribe now