Sunrise Produce saves $50,000 in fuel cost with real-time visibility

“Since we deployed Samsara across our 44 vehicles, we've saved about $250,000”

Brady Cushman, Head of IT, Sunrise Produce

Wholesale produce distribution company uses Samsara to increase operational efficiency by reducing route times and fuel costs, accelerating driver productivity, and improving product quality.

$50,000 saved in fuel costs with real-time visibility into fleet conditions on the ground.

$200,000 saved in driver overtime with Time on Site reporting and route visibility.

Improved product quality with real-time temperature and humidity monitoring.

In 1991, with one truck and a team of four, Sunrise Produce opened its doors for business with a mission to bring quality service in produce distribution to Fullerton, California. Today, Sunrise Produce is one of the leading wholesale produce distribution companies in Southern California with a 44 vehicle fleet and 150 employees on staff.

Brady Cushman, Head of IT at Sunrise Produce, was brought on board to help increase operational efficiency for the fleet. Cushman was looking for a solution that would be easy to implement and also easy to use for both drivers and the back office. With Samsara, “it was plug and play,” he said, “everything is set up and good to go right out of the box.” Within a few weeks, the team at Sunrise Produce was up and running with Samsara.

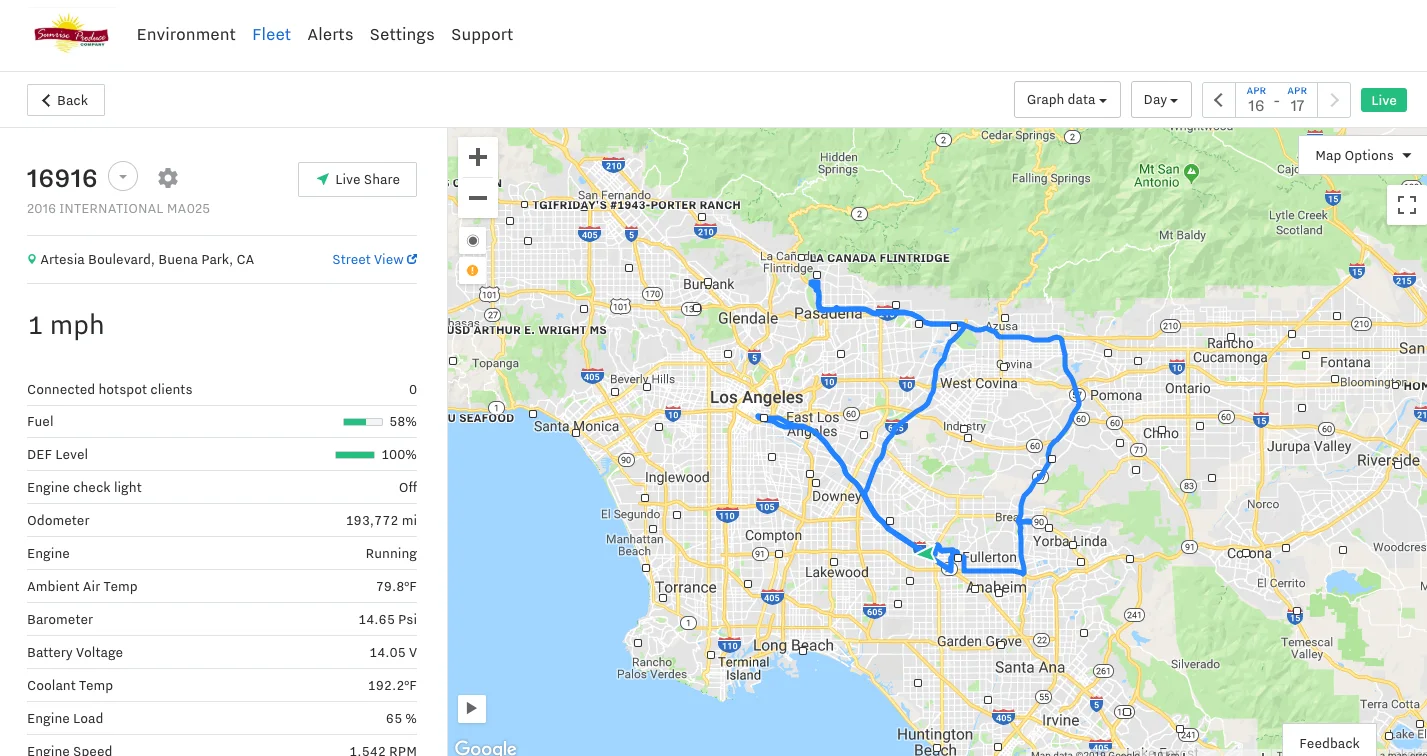

Optimizing route efficiency

Operating in Southern California, one of the most heavily congested regions of the US, accounting for time spent in traffic is par for the course. Cushman’s team regularly planned for upwards of 2 hours in overtime per route “because that’s the cost of doing business in SoCal.” As Sunrise Produce observed a steep increase in overtime, the company began to look for a solution that could help them better manage their drivers’ time and provide enhanced customer service. One of Cushman’s top requirements was historical route data for his fleet’s complex and dynamic routes.

With Samsara, he’s able to pull all of the trip history on previous stops and routes right from his dashboard and use that data to improve route planning.

“In the distribution world, you might want fewer stops with larger orders. As we push the stop count up, we can push the profitability of these trucks up,” said Cushman.

Before Samsara, their team was manually tracking and planning daily routes run, daily stop count, and daily per-truck gas in unwieldy spreadsheets. Now, Samsara automatically tracks route data, giving the Sunrise Produce team an easy way to get the insights they need to maximize the number of stops per route and increase profitability.

After implementing Samsara, the average time to complete each route dropped by 47 minutes. This reduction in time spent on the road additionally saved $50,000 in fuel for their fleet.

<div class="text-center"><a id="blog-inline-1" href="/learn-more" title="Learn more about Samsara" class="btn primary-btn teal btn--blue">Learn more about Samsara</a></div>

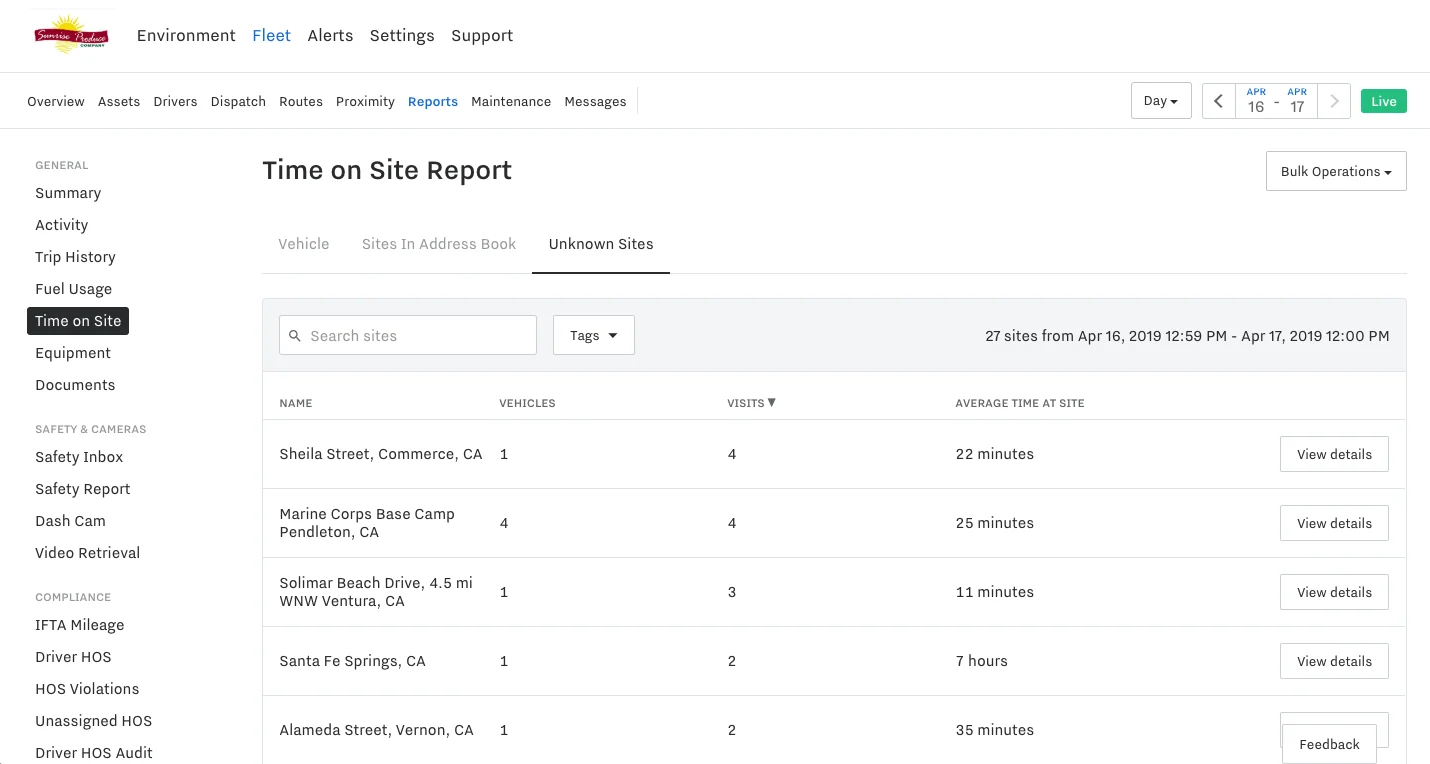

Accelerating driver productivity

Like many fleet operations around the US, the biggest operating expense for Sunrise Produce is driver pay, and it’s important for the company to ensure that drivers are maximizing their working time. Before implementing Samsara, Cushman and his team had no visibility into where their drivers were and whether they were using their time on the clock productively. Sunrise Produce uses Samsara’s Time on Site report and real-time GPS tracking to better understand how drivers are using their time.

Cushman’s team uses the Time on Site report to track the average time drivers spend at each stop. This gives Sunrise Produce visibility into where drivers are spending their time on the clock, how much time they should be spending at each site, and if they are spending time at unauthorized sites. “We’ve saved about $200,000 on driver overtime,'' said Cushman.

“We've saved about $200,000 on driver overtime”

Brady Cushman, Head of IT, Sunrise Produce

“We didn't have any system before, so guys would nap, go shopping, we had no idea what they were doing. So the savings are coming directly through managing the drivers,” said Cushman. With visibility into time on site, the team at Sunrise Produce is able to coach drivers on their productivity and more precisely plan out routes based on the average time on site for each stop.

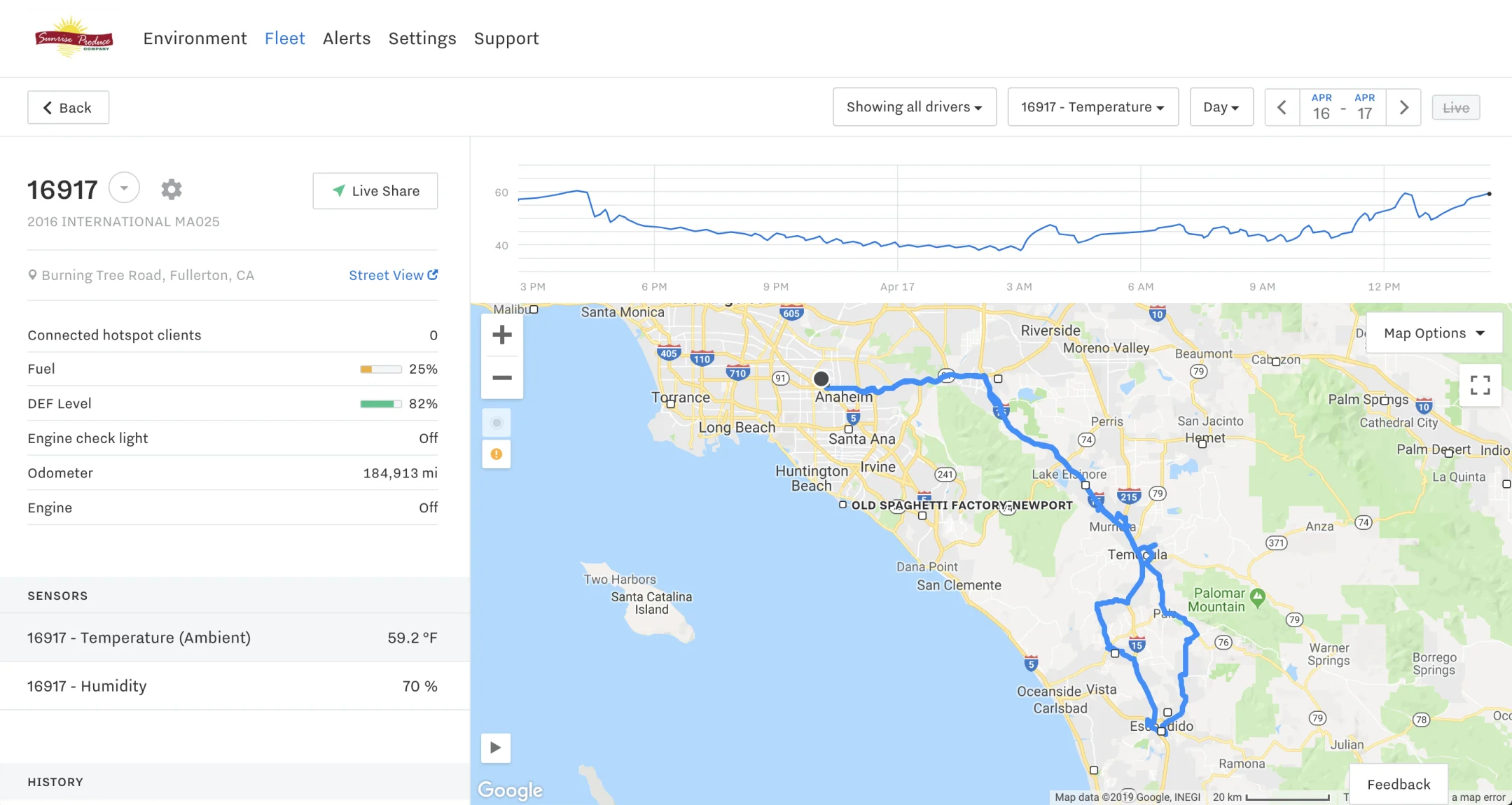

Improving product quality

For a produce delivery company, maintaining real-time temperature logs is crucial to delivering quality products to their customers. Before installing Samsara Environmental Monitors, Cushman’s team was only able to measure trailer temperatures once drivers got back from their routes. At that point it was too late to do anything if the trailer went out of the temperature range for their produce.

Now, Cushman’s team is easily able to find out if and when a cooler is breaking down so they can address it immediately. Monitoring second-by-second temperature allows the Sunrise Produce team to fix temperature issues as soon as they arise, helping to reduce losses in product year over year. They are also able to use their temperature records in the Samsara Dashboard for FSMA compliance audits.

Partnering for the future

“I knew that Samsara was cutting edge and would be taking the feedback that I was providing,” said Cushman. New features are constantly being built in the Samsara Dashboard based on feedback from customers like Cushman at Sunrise Produce to help streamline and connect operations for fleets around the world. Partnering with Samsara doesn’t stop with the technology— Sunrise Produce is able to lean on best-in-class support, available 24/7, to make sure that their operations are running smoothly and efficiently. With the pace of customer-centric innovation and an at-the-ready support team, Cushman says “I’m all in on Samsara.”

“I'm all in on Samsara”

Brady Cushman, Head of IT, Sunrise Produce

<div class="text-center"><a id="blog-inline-1" href="/learn-more" title="Learn more about Samsara" class="btn primary-btn teal btn--blue">Learn more about Samsara</a></div>

Similar posts like this

Sterling Crane Canada saves US$3M+ in equipment maintenance and replacement costs

See how Sterling Crane Canada saved $3M+ in equipment-related costs and enhanced their proactive maintenance program.

Massachusetts Bay Transportation Agency (MBTA) improves bus predictability by 10%

The Boston region’s transit authority relies on Samsara’s hardware and API to improve bus services, streamline the customer support exp...